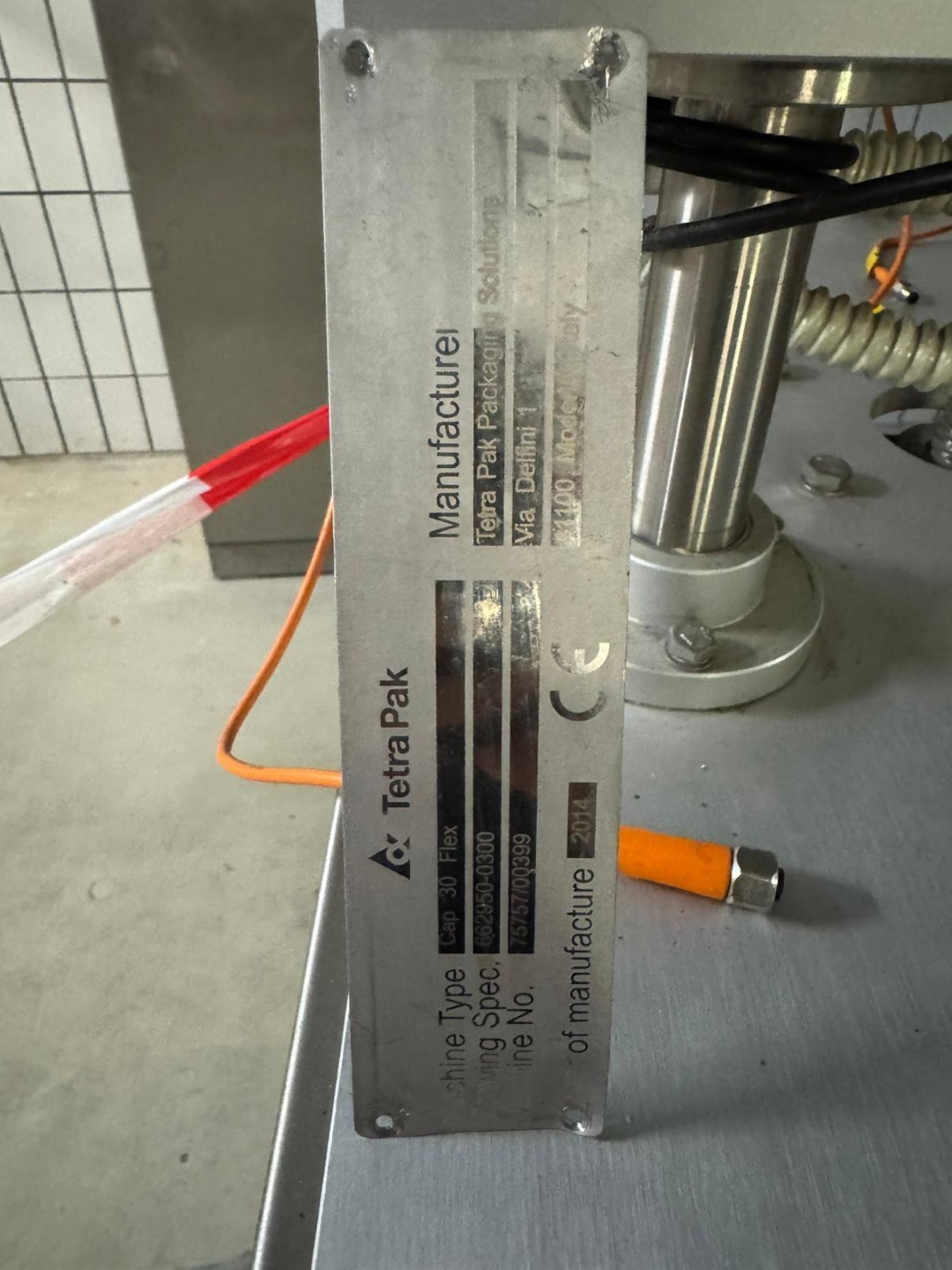

Cap applicator Tetra Pak Cap 30 Flex

Especificaciones

| Fabricante | Tetra Pak |

| Modelo | Cap 30 Flex |

| Año | 2014 |

| Condición | Usado |

| Número de Serie | 75757/00399 |

| Número de Stock | 1220 |

| Type of Machine | Cap applicator |

| Capacity | up to 8.400 caps per hour |

| Type of carton | Tetra Brik Aseptic 1.000 ml Square |

| Type of screw cap | Helicap 27 |

| Development step | - 0300 V |

| Production hours | 21.000 h |

| Buffer bunker and feeding elevator for caps | Yes, Bonino |

| Electrics | 400 / 230 V - 50 / 60 Hz - 32 A - 3 / N / PE |

| Dimensions | ± 650 x 330 x 280 cm |

| Weight | ± 3.250 kg |

Descripción

Tetra Pak Cap 30 Flex Cap applicator, previously used for Tetra Brik Aseptic 1.000 ml Square with a HeliCap 27 screwcap. This cap applicator was running in combination with a Tetra Pak TBA 8 carton filler. The applicator has a small footprint. Number of productions hours: 21.000 h. The production capacity goes up to 8.400 cartons per hour. Flexible, precise cap applicator with an auto-eject system detects and ejects packages with uneven hotmelt application or misplaced caps (out of tollerance range), glue is accurately dosed for economy and reliability. High output of on-target packages because the packages pass through the machine in a straight line without stopping or changing direction. This results in a swift but gentle handling and good package shape. Caps are applied in line as they pass through the machine which ensures accurate positioning. The positioning of the hole (as opposed to the package itself) is captured by a camera in the machine, which ensures a highly precise cap application. Cap holders are designed to move independently from one another for even greater accuracy. This feature is standard for TPA and TGA lines and unavailable for ReCap and SlimCap lines. The application of hot melt is synchronised by a servo drive. Thanks to its precise, smooth movements, the number of defects and spills is minimised. Control panel with PLC and separate operation panel with Tetra Pak touch screen panel. Nordson hotmelt unit. Including collecting vat and elevator (Bonino, code nr 44844, date 2014).