Komplette wasserfreie Milchfettlinie (AMF)

Verkauft

Spezifikationen

| Hersteller | Simon Freres + Tecnal + Flottweg + GEA Westfalia + SPX + Alfa Laval |

| Modell | Contimab MC30 + Buttersilo + Z42-3/441 + MSE 120-01-777 |

| Jahr | 1988 |

| Zustand | Gebraucht |

| Lagernummer | 1257 |

| Maschinentyp | Linie wasserfreies Milchfett (AMF) |

| Kapazität (Eingang) | bis zu 9.500 Liter pro Stunde |

| Bodenfläche | ± 12 x 10 Meter |

| Gewicht | ± 10.000 kg |

| Kapazität | Liter pro Stunde |

| Stufen | 2 Stufen mit Micro-Gap-Ventil |

| max. Druck | 172 bar |

| Ventilzylinder | Sitzventile |

| Kolbendurchmesser | 76 mm |

Beschreibung

Komplette AMF-Linie (wasserfreies Milchfett), auch bekannt als Butteröl, ein konzentriertes Milchprodukt, das durch Entfernen

fast das gesamte Wasser aus frischer Butter oder Sahne, was zu einem Produkt mit mindestens 99,8 % Milchfett führt. Es hat eine

reichhaltigen, cremigen Geschmack und eine glatte Textur, so dass es weit verbreitet in der Back-, Süßwarenindustrie und für die

Herstellung von Speiseeis und rekombinierten Milchprodukten. Die komplette Linie besteht aus:

* Kontinuierliche Butterherstellungsmaschine - CBM, Hersteller Simon Freres, Modell Contimab Major MC 30, Kapazität bis zu einem Durchfluss

Leistung von 3,5 Tonnen/h mit Mischer. Intern modifiziert, um mit einer Zufuhr von 9.500 l Sahne pro Stunde zu arbeiten.

* Edelstahl-Netzfilter, Hersteller Sassaro, Baujahr 2015.

* Geschlossenes Buttersilo aus Edelstahl, Hersteller: Tecnal / Simon Freres mit Auslaufpumpe.

* Plattenwärmetauscher (PHE), Hersteller SPX, Modell H, als Heizgerät verwendet.

* Als Kühler wird ein Plattenwärmetauscher (PHE), Hersteller Alfa Laval, Modell P14, verwendet.

* 2x Lagertanks, Volumen 5000 Liter, isoliert, mit Rührwerk.

* Dekanter, Hersteller Flottweg, Modell Z42-3/441, Baujahr 1988, inkl. Tanks, Pumpen und Filter.

* Plattenwärmetauscher (PHE), Hersteller SPX, Modell H, wird als Pasteurisierungseinheit verwendet.

* Schmelzkreislauf mit Entgaser und Kondensator, Hersteller Alfa Laval / Prominox.

* Rahmkonzentrationsseparator, Hersteller GEA Westfalia, Modell MSE 120-01-777, Baujahr 2018, Seriennummer 1737-639,

Kapazität bis zu 5 Tonnen/h, ohne Prozesswasser.

* Elektrischer Warmwasserspeicher zur Rohrverfolgung.

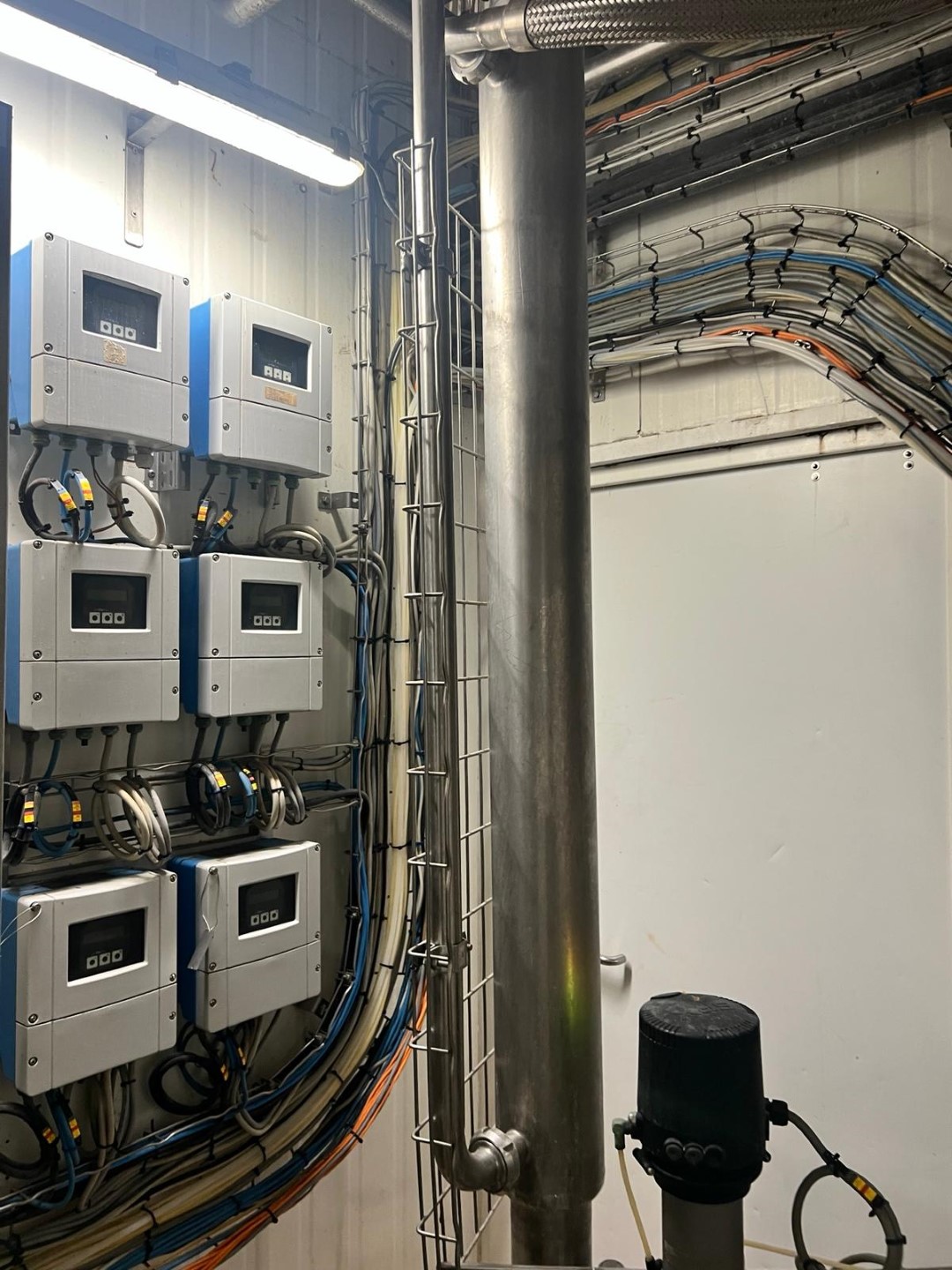

* Elektroraum mit Strom und SPS

* Mimik- und Betriebsbildschirme und Produktionsberichte.

* Alle Verbindungskabel, Rohrleitungen, Ventile und Pumpen.