GEA Laguilharre - 5x Bi-thermal Effect TVR Evaporator with Direct Steam Injection (DSI)

Specifications

| Manufacturer | GEA Laguilharre |

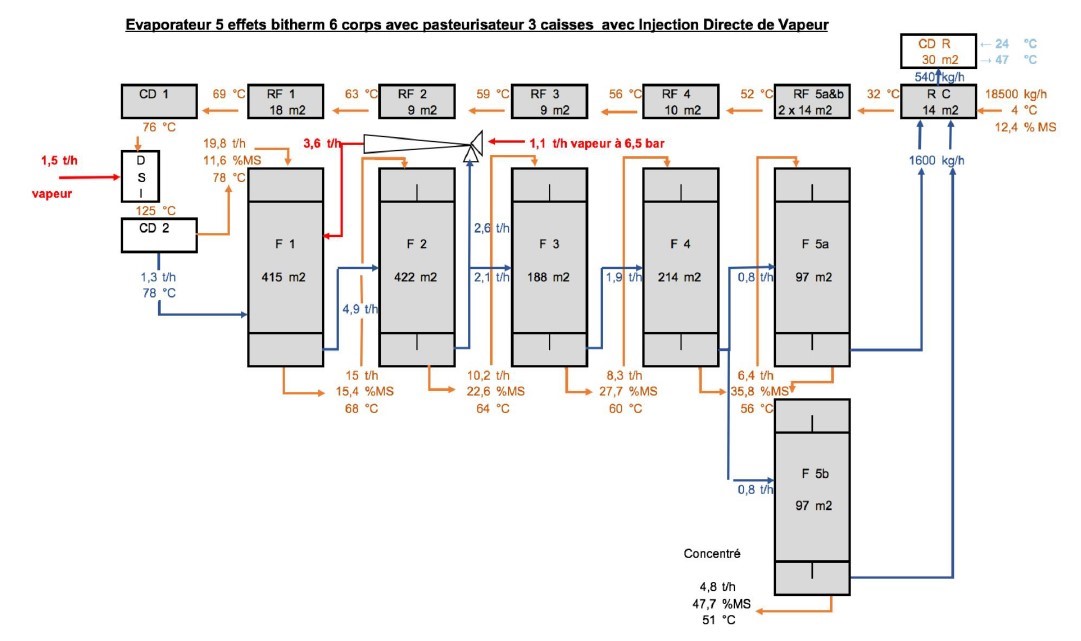

| Model | 5x Bi-thermal Effect TVR Evaporator with Direct Steam Injection (DSI) |

| Year | 1981 |

| Condition | Used |

| Serial Number | 55478 |

| Stock Number | 1467 |

| Type of Machine | Evaporator |

| Stages | 5x Bi-thermal |

| Compression | 2-stage TVR |

| Product | Infant milk (skim / whole milk) |

| Capacity input | 15.500 kg/h to 21.000 kg/h (± 8,5% TS) |

| Water Evaporation | 11.400 kg/h to 13.800 kg/h |

| Concentrate | 4.100 kg/h to 7.200 kg/h (up to 48% TS) |

| Modification year | 2000 (DSI injection) |

Description

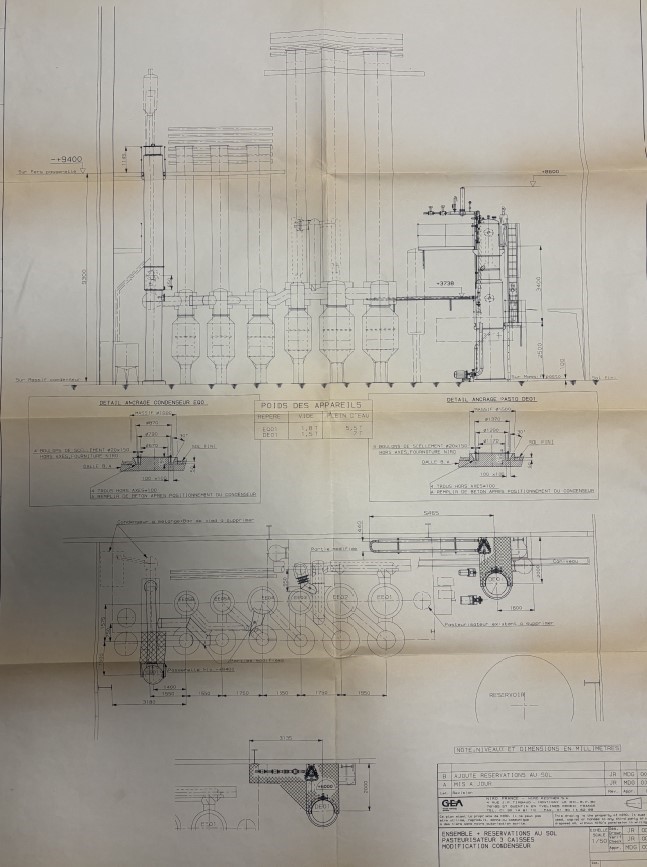

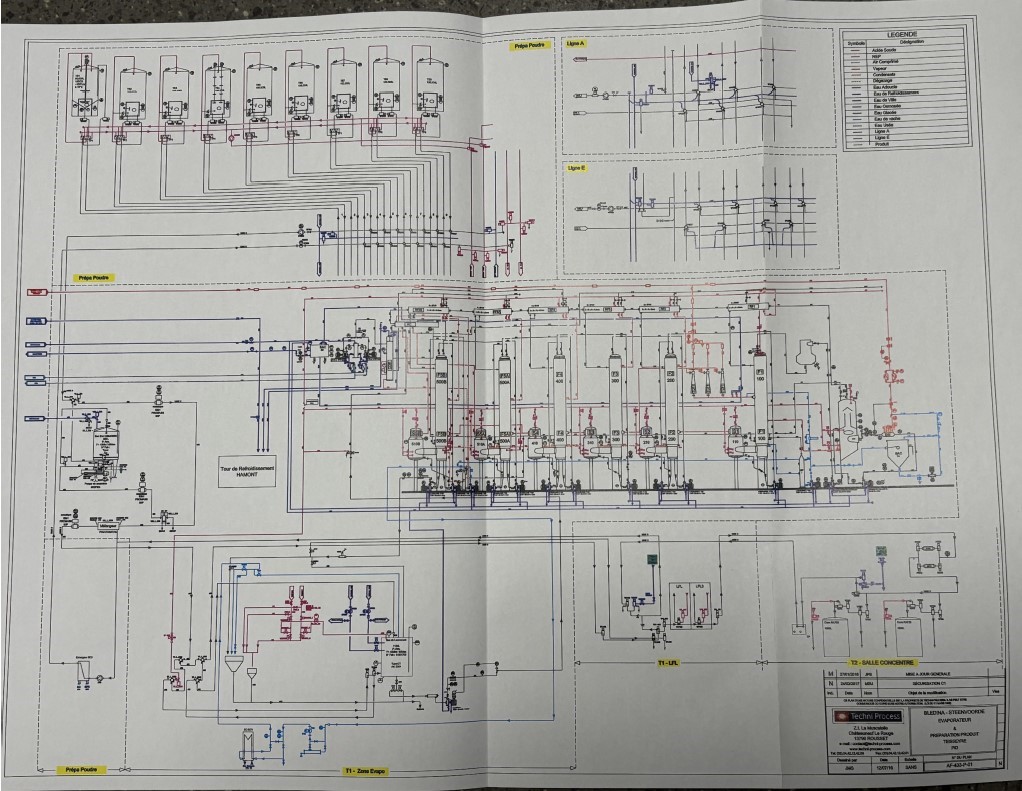

Complete falling film vacuum evaporator, previously used for infant milk, consisting of 5 bi-thermal effect TVR Evaporator with a direct steam injection (DSI) pasteurizer and an expansion chamber. Still mounted in the Danone plant in France till end of March 2026. The product feed rates in the installation can vary between 14 and 23 t/h with a comparative temperature between 78 and 54°C from the 1st to the 5th effect. The system is heated primarily by injecting steam into the thermo-compressor. The preheating of the incoming product is achieved via tubular heaters supplied by vapours drawn from the beams. A direct steam injection pasteurizer and expansion chamber is provided to pasteurize the product in a range of 118 to 133 °C.

Line modified in 2000 to replace the mixing condenser with a tubular condenser and installing the heat treatment with direct steam injection.

The evaporator is used to concentrate 4 product categories:

- Lean hydrolyzed products pasteurized at 125°C.

- Lean or fat fermented products pasteurized at 118°C.

- Pre-organic products pasteurized at 118°C.

- Compact products pasteurized at 133°C.

Processing rates used by the current dairy:

- Skim / whole milk - infeed flow 15.500 kg/h - evaporation 11.400 kg/h - outfeed flow 4.100 kg/h.

- Skim / whole milk - infeed flow 17.000 kg/h - evaporation 12.300 kg/h - outfeed flow 4.700 kg/h.

- Skim / whole milk - infeed flow 21.000 kg/h - evaporation 13.800 kg/h - outfeed flow 7.200 kg/h.

- Cleaning: flow 23.000 kg/h

Production times vary between 14,5 and 15 hours, and monitoring is carried out on samples taken from the output of beams 3 and 5b for thermophilic bacteria. The pH of the concentrate is also monitored. The results of the bacteriological monitoring can also be used as criteria for shortening processing times.

Additional features:

- Dismantling possible from 01-04-2026 (line in production till this date).

- Dismantling and loading in containers/trucks will be taken care of by Hamburg Machinery and is included in the price.

- Big set of spare parts included (purchase value EUR 90.000,-), list can be presented on request.

- Software and PLC program is excluded (integrated in the complete system of the dairy of Danone).