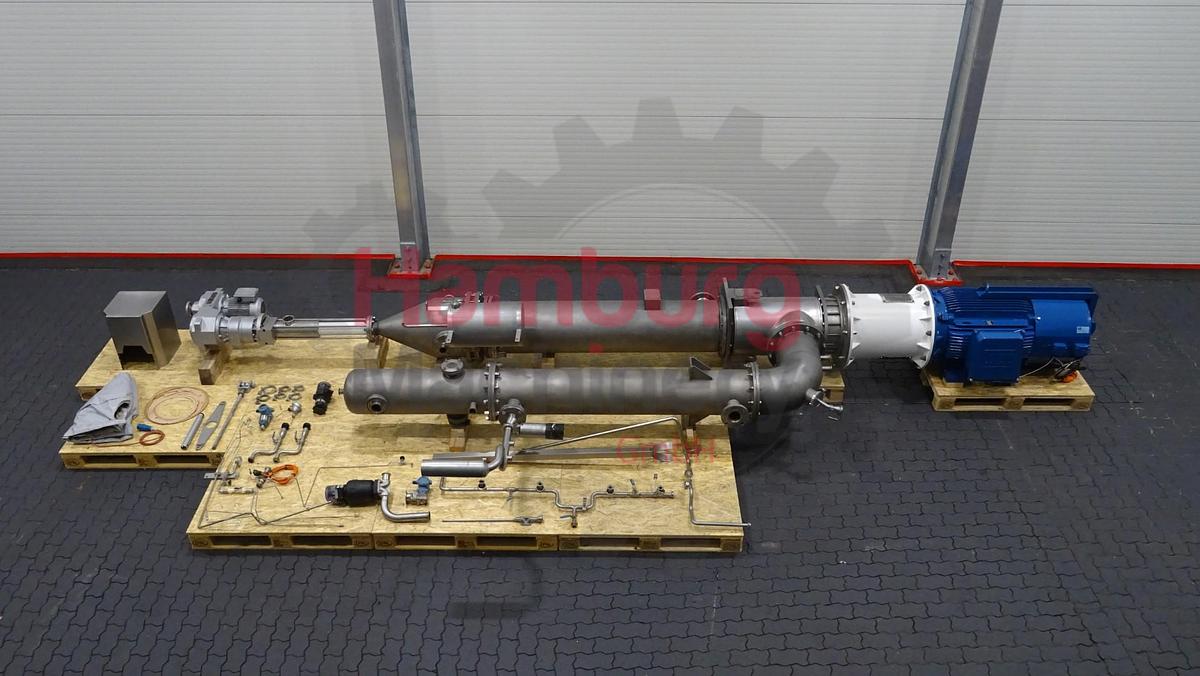

Luwa SMS GmbH LN-0200 - Vertical Thin Film Evaporator

Specifications

| Manufacturer | Luwa SMS GmbH |

| Model | LN-0200 - Vertical Thin Film Evaporator |

| Year | 1981 |

| Condition | Used |

| Serial Number | 0200/57 |

| Stock Number | 1435 |

| Type of Machine | Vertical Thin Film Evaporator |

| Product | Dairy products |

| Heating surface | 21,5 Sq. Ft. |

| Internal volume | 280 Liter |

| Jacket volume | 26 Liter |

| Max. Heating Medium Pressure (according ASME U-Stamp) | Body: 165 PSIG - 370°F / 120 PSGI - 650°F |

| Internal pressure | Vacuum up to atmospheric pressure |

| Motor | 75 kW - 415 V - 173 A - 740 rpm - 50 Hz |

| Rotor speed | 402 rpm |

| Dimensions | ± 5,5 x 2,0 x 0,6 mtr |

Description

Luwa SMS GmbH LN-0200 - Vertical Thin Film Evaporator consist of a cylindrical, vertically-arranged body with heating jacket. A rotor inside the body is equipped with rows of pendulum blades along the full length of the dryer.

Special thin-film evaporator designed for dairy service, discharge system, vapor pipe, condenser, and drives. It was in used as a pilot plant on a dairy service until early 2001 and afterwards converted to a 2 square metre cheese base processor with discharge system and ran till 2025 in a Casein plant in a dairy factory in New Zealand.

The vertical thin film dryers operate as follows: The wet feed is spread by the pendulum blades in a thin layer onto the heated wall. During this process, the volatile components evaporate continuously out of the product layer at high evaporation rates. The pendulum blades are designed with a minimum gap to the heated wall to prevent fouling deposits on the heating surface, which would reduce performance. The product enters the dryer at the top. Evaporation starts immediately after the boiling point has been reached. First, solids are formed in the slurry zone. The material is then dried to powder under continued shearing by the pendulum blades. The final solid product is discharged by gravity at the bottom of the dryer via a suitable air lock. The operation principle and the design of the vertical thin film dryers offer unique advantages: From liquid to solid in one step, little product hold-up, short residence time, vacuum and atmospheric operation and high performance even with fouling substances. Typical applicatons: drying of salts such as chlorides, bromides, sulphates, carbonates, xanthates, phospates and neutralisation salts, wastewater treatment, silane recovery, silicone drying or glycerine recovery.

Heating surface: 21,5 Sq. Ft. Max. Heating Medium Pressure (according ASME U-Stamp): Body: 165 PSIG - 370°F / 120 PSGI - 650°F. Internal pressure: Vacuum up to atmospheric pressure. Product wetted parts: T316L SS or 316 Ti. Volume internal: 280 liter. Volume jacket: 26 Liter. Motor: 75 kW - 415 V - 173 A - 740 rpm - 50 Hz. Bottoms Pump: Allweiler-Seeberg Type SNBP 100.2 VI PI K22 LL 4003 with special auger for product removal from bottom cone.