Complete can filling and closing line for babyfood powder with scoop / spoon in 400 gram or 800 / 850 / 900 gram aluminium cans

Specifications

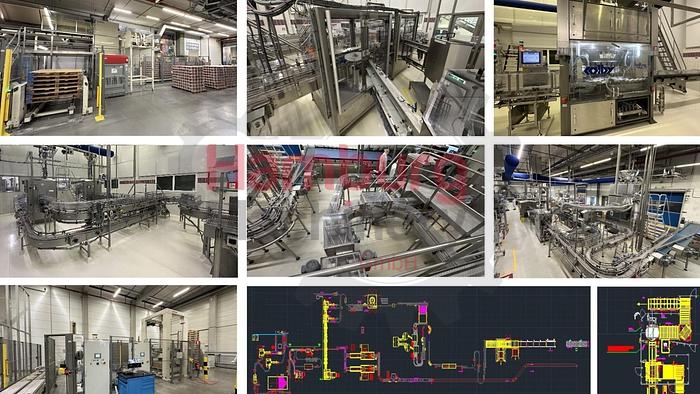

| Manufacturer | Jorgensen, Hoppmann, Mannesmann Dematic / Colby, NSM, Ferrum, R. Laurent, Involvo and Cyklop |

| Model | De-palletiser, Can Rinser, Scoop machine, Filling machine, Seamers, Snap capper, Packer, Palletizer |

| Year | 2000 |

| Condition | Used |

| Serial Number | OA 4038-40 / 14.214008.01 / PAJOL-45958-01-10 / 341-79700-1-2-3 / 20-272 / 19 |

| Stock Number | 1200 |

| Type of Machine | Complete can filling and closing line for babyfood powder with scoop |

| Product | Baby / Infant milk powder |

| Can format | Diameter 99 mm, filling weight 400 gram and diameter 127 mm, filling weight 800 / 850 / 900 gram |

| Capacity | 400 gram: 18.500 cans per hour and 800 / 850 / 900 gram: 10.200 cans per hour |

| Scoop / spoon available | Yes |

| Dismantling included in the price | Yes |

| Fixed dismantling date | 24-07-2025 till 27-07-2025 (3 days only), production till 23-07-2025 |

Description

Complete can filling and closing line for babyfood milk powder or other powders with scoop / spoon in 400 gram or 800 / 850 / 900 gram aluminium cans

Product: Baby food milk powder or other powders.

Formats:

- Diameter 99 mm, filling weight 400 gram

- Diameter 127 mm, filling weight 800 / 850 / 900 gram

Capacity:

- 400 gram: 18.500 cans per hour

- 800 / 850 / 900 gram: 10.200 cans per hour

Fixed dismantling date:

- 24-07-2025 till 27-07-2025 (3 days only).

Line exisiting out of:

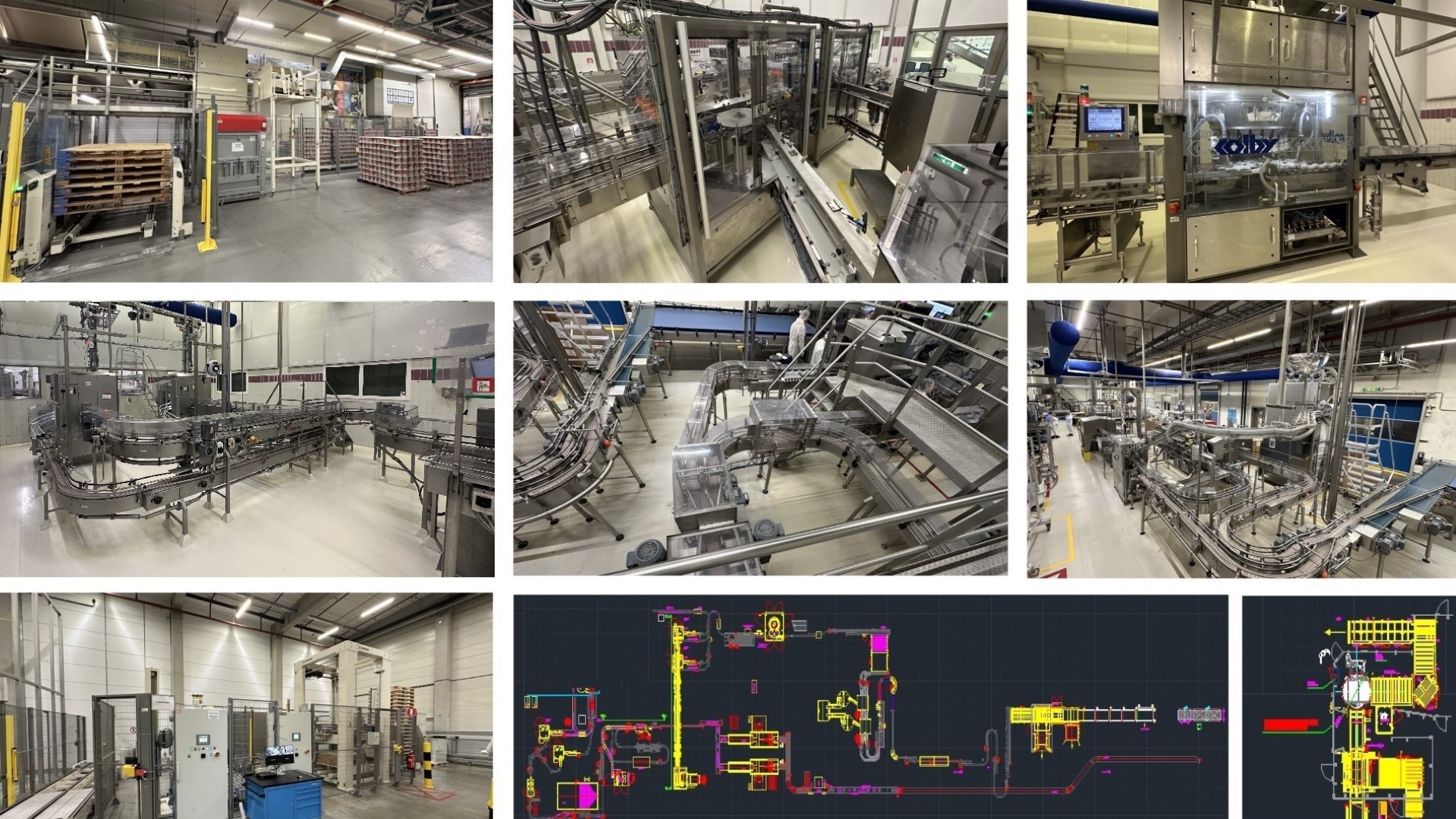

1. Preformed can de-palletiser machine, separate layer by layer from the pallet

Manufacturer: Jorgensen

Year: 2000

Ref. No.: OA 4038-40

Drawing no: 210-020 DPL. 01

Control panel with 10x Danfoss VLT Midi Drive frequency converters and Siemens S7 PLC.

2x Simatic operation panels around the machine.

Infeed buffer conveyor for 5x block pallets.

Pallets with 8x layers of 850 gram cans with carton separation between each layer.

Troax fench cover around the infeed conveyor.

Collection station for empty pallets.

2. Eagle vision can control system (excluded)

3. Can rinser (by air), turning the cans upside down, including ionization unit to make the cans anti-static.

4. UV tunnel (excluded)

5. Divider conveyor to make 2-lines.

6. Scoop/Spoon ”filling” machine (scoop dropper) existing out of 2x separate adding stations of the scoops / spoons, including 1 big scoop buffer vat for dumping plastic bags unsorted scoops, 2x scoop transport conveyors to the 2x sorters and feeding conveyors to the scoop adding machine.

Manufacturer: Hoppmann

Year: 2014

Machine number: 14.214008.01

Production hours: System 1: 69.577 h, System 2: 70.526 h (09-12-2024)

Capacity: 360 scoops/min (180 per system)

Power: 400 V – 3,9 kW – 9 Amp

Dimensions: ± 640 x 450 x 270 cm

Weight: ± 3.500 kg

7. Buffer table for cans with a scoop / spoon.

8. Scoop vision control unit

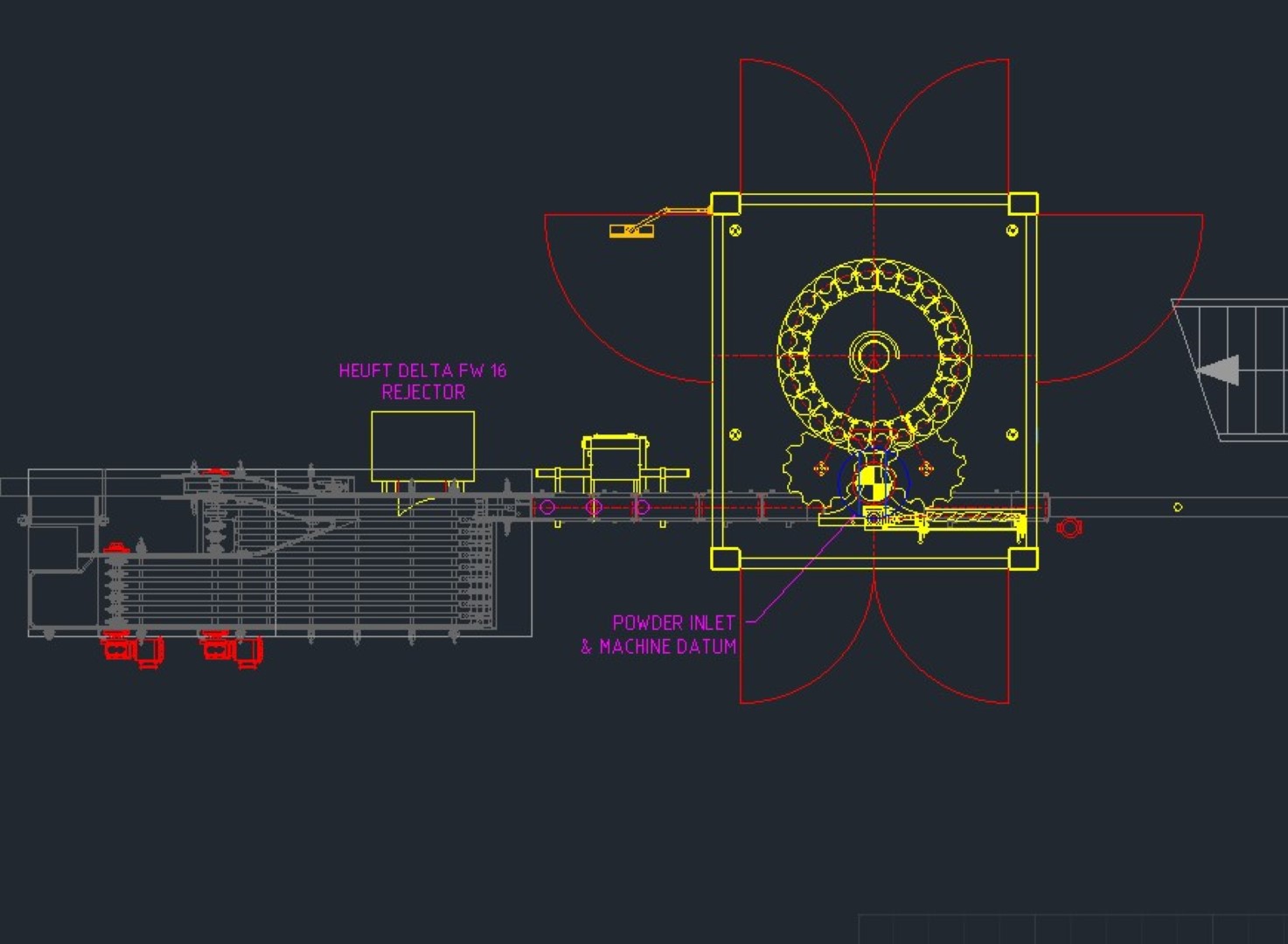

9. Baby food powder filling machine with rejector and rejector table.

Manufacturer: Engineering Mannesmann Dematic / Colby Powder Systems

Machine type: CRF 24H

Serial number: PAJOL-45958-01-10

Year: 2000

Power: 400 V – 50 Hz

Capacity: up to 300 cans per minute (99 mm can) and up to 150 cans per minute (127 mm can)

Dimensions filler: ± 230 x 265 x 330 cm

Weight: ± 7.700 kg

Infeed metering scroll.

24-Head Colby filler for baby food powder.

Gross weigher with feedback to the machine for adjustment to the target weight, Mettler Toledo Garvens, type C3570, year 2020, min 360 gram, max 1400 gram.

Rejector and reject table

Infeed rotary valve, powder transfer tube, 3 sifters and vibration tube.

10. Bottom unpacker, transport conveyor and bottom (partly) seamer

Bottom unpacker:

Manufacturer: NSM Magnettechnik

1x machine for 2 formats, string of 99 mm and string for 127 mm bottoms for cans, easy format change.

Canline rope conveyor, year 2020, code 10126742

2x (partly) bottom seamers

A: Manufacturer: Ferrum

Type: F504EC

Date: 2000

No: 341-79702

For 127 mm cans

B: Manufacturer: Ferrum

Type: F505EC

Date: 2000

No: 341-79700

For 99 mm cans

11. Control station in the high care room, SCADA package and Software licences excluded. PLC and copy program available.

12. 4x Gaz boxes for filling the cans with gaz (excluded).

13. 2x Final bottom seamers

A: Manufacturer: Ferrum

Type: F504EF

Date: 2000

No: 341-79703

For 127 mm cans

B: Manufacturer: Ferrum

Type: F505EF

Date: 2000

No: 341-79701

For 99 mm cans

14. Control system Heuft.

15. Buffer table.

16. Outside can brushing unit, sweep the dust off (excluded).

17. Sticker machine and leaflet inserter

Manufacturer: Pago

2-stations

Vision unit, Jörgensen (excluded).

18. Plastic snap cap buffer vat and adding machine

Plastic snap cap buffer vat for dumping carton boxes with unsorted caps

Manufacturer: R. Laurent SA

Modele: C32

Year: 2003

Serial number: 20-272

Conveyor (air blown) from the buffer vat to the snap cap adding machine

Snap cap adding machine

Manufacturer: R. Laurent SA

Modele: C1

Year: 2003

Serial number: 19

19. Eagle vision control system of the cans (excluded)

20. 2x Wrap around case packers

Manufacturer: Involvo

Year: 2000

Robatech hotmelt units, model Concept Diamond 8/4, year 2015

1x Machine for 99 mm cans (6x4 per carton).

1x for 127 mm cans (4x3 per carton).

21. Scade control system in end of line packaging area (excluded).

22. Palletizer and stretch foil machine

Palletizer

Manufacturer: Jorgensen

Feeding of empty pallets station

5 boxes of 12 cans of 800 / 850 / 900 gram per layer

Stretch foil machine

Manufacturer: Cyklop

Type: CST 940

Outfeed station.

23. Including interconnecting conveyors, control panels, PLC and programs for PLC's,

Excluding interconnecting conveyors between wrap round case packers (item 20) and palletizer (item 22), all inkjet printers, UV tunnel, Gaz boxes and all eagle vision units (will be re-used by the Supplier).

Dismantling will be done by the Supplier.

Fixed dismantling date: 24-07-2025 till 27-07-2025 (3 days only).

Because of the tight dismantling schedule, not all cables can be labelled, so cables will be cut if necessary. Also mechanically parts can be cut instead of dismantled in a proper manner.

A supervisor (or dismantling team) from the Buyer can be present on site during the dismantling.

Machines will be moved from the factory by a truck to an outside parking place of the outside of the building. All machinery needs to be loaded / trucks to be organised by the Buyer himself (support by Hamburg Machinery on request).