GEA Filtration Ceramic MF Plant + HTS Plant

Specifications

| Manufacturer | GEA Liquid Processing Scandinavia A/S - GEA Filtration |

| Model | Ceramic MF Plant + HTS Plant |

| Year | 2004 |

| Condition | Used |

| Serial Number | 100118 |

| Stock Number | 1218 |

| Type of Machine | Ceramic MF Plant + HTS Plant |

| CMF Capacity input | 11.273 liter per hour |

| CMF Retentate output | 564 liter per hour |

| CMF Permeate output | 10.709 liter per hour |

| HTS Capacity input | 1.553 liter/h @ 26% fat (mixture of 40% cream and retentate from the Ceramic Microfiltration Unit) |

| HTS Temperature program | 55 - 130 - ± 55 °C |

Description

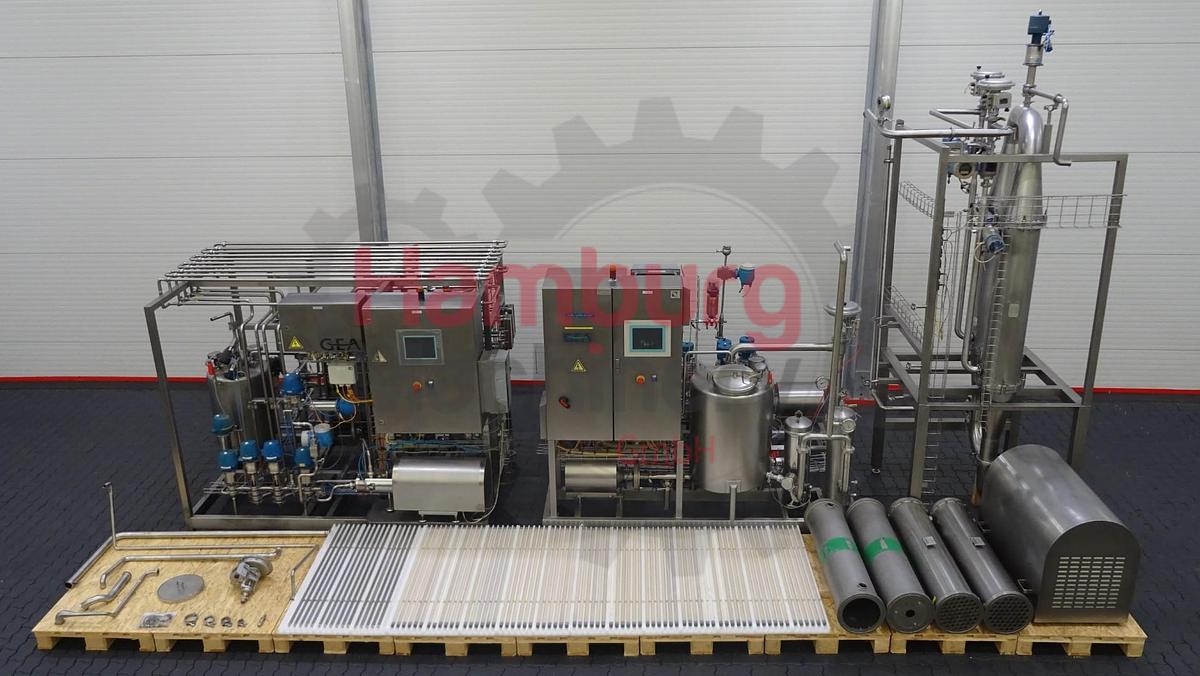

Skid mounted GEA Filtration ceramic Micro Filtration (MF) plant combined with a GEA Filtration High Temperature System (HTS) plant for bacteria and spore reduction in cheese milk. Previously running in a cheese plant in Europe.

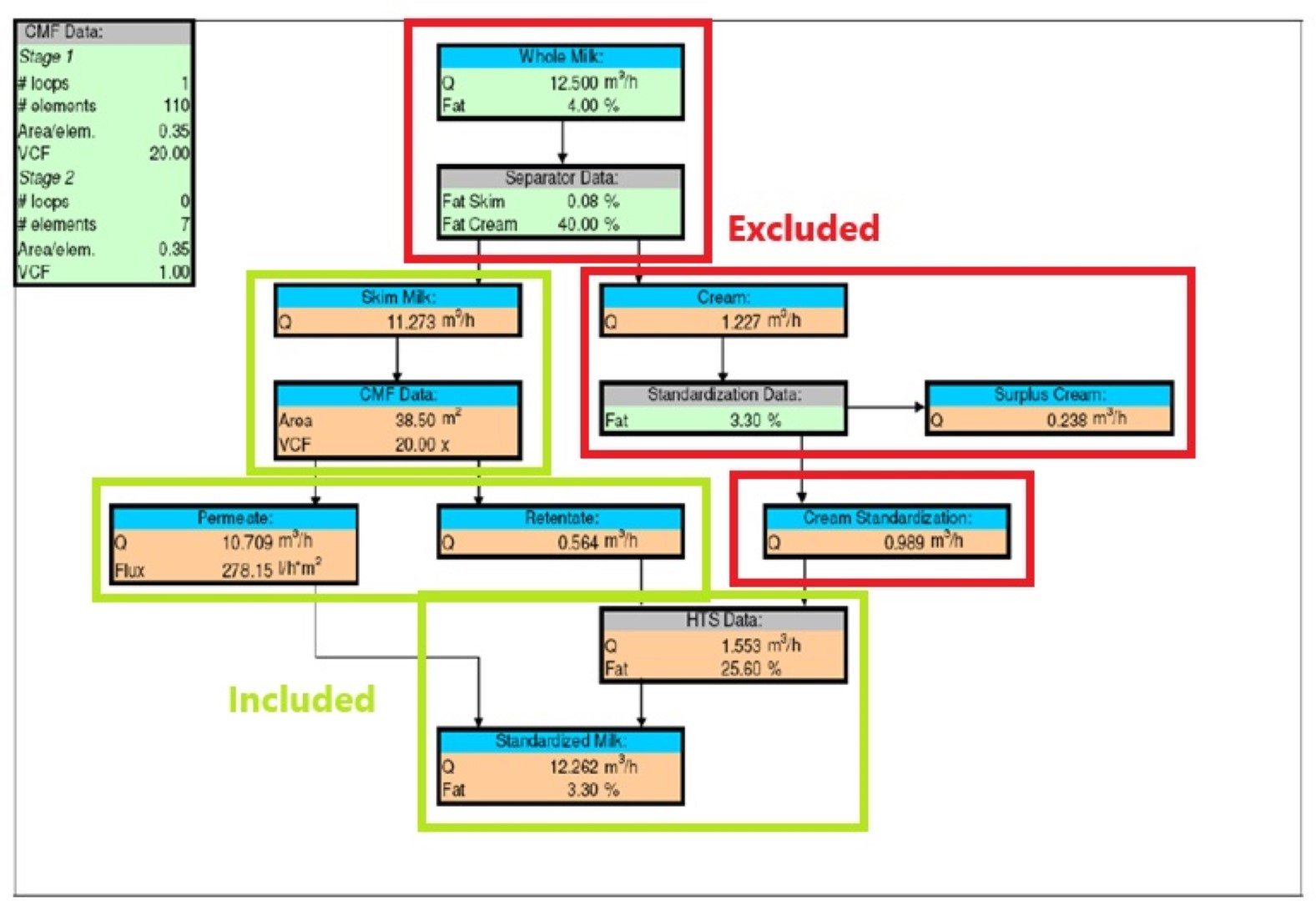

First the milk has to be skimmed by a milk skimmer / separator (separator excluded), skim milk will enter the CMF unit, the skim milk will be filtrated, the bacterias and spores (retentate) will be sent to the HTS unit, the cream will be sent to the standardization device (excluded), after standardization the cream will be sent to the HTS unit, both (retentate and standardized cream) will be sterilized on high temperature in the HTS unit, after the HTS unit the skim milk, the sterilized retentate and standardized cream will be added together again. The whole set is designed for 12.500 m3/h with 4% fat input and an output of 12.262 m3/h with 3,3% fat (surpluss of cream of 0,238 m3/h).

The whole milk must not prior to this pretreatment, have been exposed to any kind of heat treatment such as thermization or pasteurization, as well, the milk must not have been exposed to homogenization.

Project number: 100118.

The line exist out out of 2 different sections:

- Section 01: Ceramic Micro Filtration plant, according flow sheet: 100118-11002.

Input capacity: 11.273 liter/h of skim milk.

Permeate output: 10.709 m3/h

Retentate output: 0,564 m3/h ("bacterias and spores" which will go afterwards to the HTS unit)

Process temperature: 52 °C

Year of manufacturing: 2004

The skid mounted CMF unit exist out of 2 skids with:

- Feed / CIP Section with balance tank for feed and CIP, centrifugal feed / CIP pump (Fristam FPE 712A, serial nr 0424530218, motor 4 kW - 400 V - 50 Hz - 2.885 rpm), plate heat exchanger for CIP and sanitizing, pre-filter, level and temperature transmitters, sample point, piping and valves.

- Filtation Loop, total filter area ± 38,5 m2 with 2x membrane housings with each 55 ceramic membranes (110 ceramic membranes OD25x1178 23 chs 1,4 μm ISOFLUX, 0,35 m2 in total), booster pump (Fristam FPE 1252A, serial nr 0475490047, motor 75 kW - 400 V - 50 Hz - 2.975 rpm), transmitters, sample point, piping and valves.

- Rententate Section with flow transmitter, control valve, sample point, piping and valves.

- Permeate Section with pressure indicator, sample point, piping and valves.

- Stainless steel control panel with motor controls, 3x frequency converters (Danfoss, 2x 4 kW and 1x 75 kW), fuses, main switch, emergency stop, Siemens S7 PLC CPU Serie 300 and Siemens TP270 HMI with 10'' touch panel.

Including 2x extra membrane housings with each 55 ceramic membranes and 2x extra dummie housings for installation help.

- Section 02: High Temperature System plant, according flow sheet: 091270-11001

Input capacity: 1.553 liter/h @ 26% fat (mixture of 40% cream and retentate from the Ceramic Microfiltration Unit).

Temperature program: 55 - 130 - ± 55 °C.

Year of manufacturing: 2010

The skid mounted HTS unit exist out of 1 skid with:

- Feed / CIP Section with balance tank for feed and CIP (100 liter), product booster / CIP pump (Highspin twinscrew pump), transmitters, sample point, piping and valves.

- Plate Heat Exchanger Section with PHE (Alfa Laval M6-MBase, 20107-13626, 2010), holding cell, transmitters, sample point, piping and valves.

- Hot Water Section with brazed plate heat exhanger, water pump (Grundfos), transmitters, sample point, piping and valves.

- Safety Cooler Section with brazed plate heat exchanger, piping and valves.

- Stainless steel control panel with motor controls, frequency converter, fuses, main switch, emergency stop, Siemens S7 PLC CPU 315-2PN/DP 256 kB and Siemens MP 277 HMI with 10'' colour screen touch panel.

Flowscheme and manuals of both units in English available.