Aseptische PET-Flaschen-Abfüllmaschine KHS Innosept Absofill / ABF 710/03

Verkauft

Spezifikationen

| Hersteller | KHS AG |

| Modell | Innosept Absofill / ABF 710/03 |

| Jahr | 2009 |

| Zustand | Gebraucht |

| Seriennummer | 710/11-12 K021 |

| Lagernummer | 1302 |

| Maschinentyp | Aseptische PET-Flaschenabfüllmaschine |

| Kapazität | 12.000 Flaschen/h @ 250 - 1.000 ml, 10.000 Flaschen/h @ bis 1.500 ml und 8.000 Flaschen/h @ bis 2.000 ml |

| Nenndurchmesser des Flaschenhalses | 38 mm |

| Stützringdurchmesser | 43 mm |

| Aktuelle Produkte | Proteinshakes und Milchgetränke (kalt abgefüllt) |

| Hülle des Lebens der aktuellen Produkte | 9 Monate Garantie |

| Produktionsstunden | 62,371 Stunden |

| Kapazität Basisprodukt (Eiscreme) | 100 - 2.000 ltr/h |

| Verfügbar pro | Januar 2026 |

| Elektrik | 400 V – 3 Ph – 50 Hz – ± 125 kW |

| Gesamtabmessungen | ± 900 x 240 x 600 cm |

| Gewicht | ± 9.500 kg |

| Kapazität Feinstvermahlung - Siebrückstand 20-50% | 180 - 300 kg/h |

| Kapazität Feinmahlung - Siebrückstand 51-62% | 300 - 500 kg/h |

| Kapazität Espressomahlung - Siebrückstand 63-69% | 500 - 650 kg/h |

| Kapazität Südeuropäische Vermahlung - Siebrückstand 70-80% | 650 - 700 kg/h |

| Kapazität Filtermahlung - Siebrückstand 81-89% | 700 - 850 kg/h |

| Kapazität Espressomahlung - Siebrückstand von 63-69% | 500 - 650 kg/h |

| Kapazität Südeuropäische Vermahlung - Siebrückstand von 70-80% | 650 - 700 kg/h |

| Kapazität Feinstvermahlung und einem Siebrückstand von 20 - 50 % | 180 - 300 kg/h |

| Kapazität Filtermahlung - Siebrückstand von 81-89% | 700 - 850 kg/h |

| Band | 130 Liter |

| Kapazität Feinmahlung und ein Siebrückstand von 51 - 62 % | 300 - 500 kg/h |

| Kapazitätsbestandteile | 10 - 200 ltr/h |

| Kapazität Espressomahlung und einem Siebrückstand von 63 - 69 % | 500 - 650 kg/h |

| Volumentrichter | 40 Liter |

| Kapazität Südeuropäische Vermahlung und ein Siebrückstand von 70 - 80 % | 650 - 700 kg/h |

| Zeichnungsspezifikation | 59717520654 |

| Kapazität Filtermahlung und ein Siebrückstand von 81 - 89 % | 700 - 850 kg/h |

| Kapazität Basisprodukt | 100 - 2.000 ltr/h |

| Doppelt ummantelt | Nein |

| Isolierung | Nein |

| Art des Rührwerks | Hochgeschwindigkeitslaufrad im Boden des Tanks |

| Motor des Rührwerks | kW - 380 V - U/min - A |

| Anzahl der Fuß | 4x |

| Innenmaße | cm |

Beschreibung

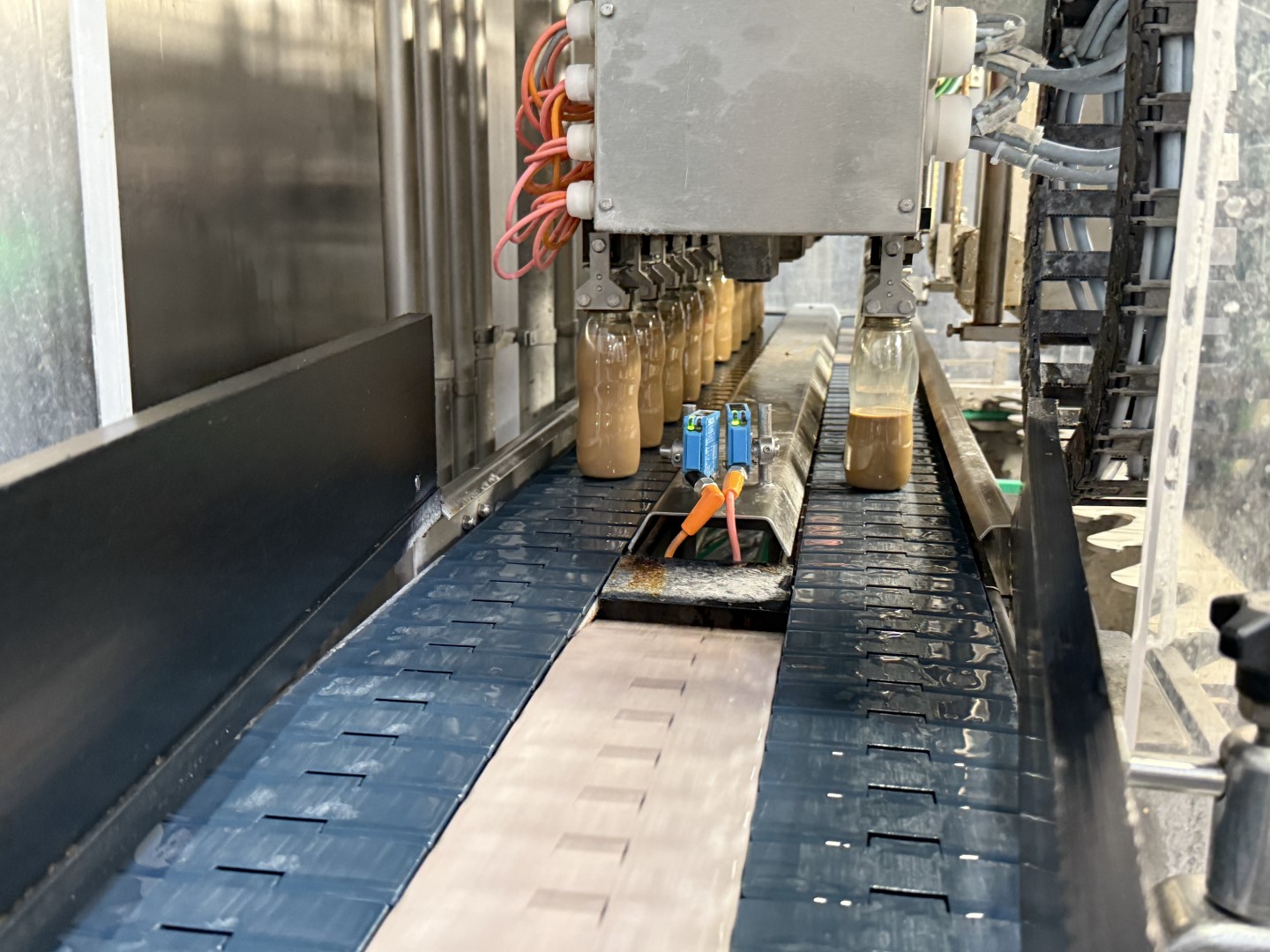

Im Auftrag unseres Kunden verkaufen wir diesen Innosept Asbofill ABF (Aseptic Bottle Filler), 10-spurig, PET-Flaschenabfüller

Maschine, die für die aseptische Abfüllung von flüssigen, stillen, mikrobiologisch empfindlichen Hoch- und Niedrigtemperatur-

Säureprodukte in vorgefertigte Plastikflaschen. Der Kunde kaufte eine neue und größere aseptische Abfüllmaschine für

Erweiterung seiner Produktionskapazitäten. Diese aktuelle Maschine wird im Januar 2026 verfügbar sein. Demontage und Entfernung

Die Entsorgung aus der Fabrik erfolgt durch die Molkerei.

Die Maschine wurde in den letzten 8 Jahren zum Abfüllen von Proteinshakes und Milchgetränken (Kaltabfüllung) in der aktuellen Fabrik verwendet.

Früher wurde es für Fruchtsäfte verwendet. Haltbarkeit der aktuellen Produkte: 9 Monate garantiert. Kapazität: 12.000

Flaschen/h @ 250 - 1.000 ml, 10.000 Flaschen/h @ bis 1.500 ml und 8.000 Flaschen/h @ bis 2.000 ml. Füllgenauigkeit: ± 2

ml (Füllvolumen <1.000 ml) und ± 0,2% (Füllvolumen >1.000 ml). Flaschenhals-Nenndurchmesser: 38 mm. Mit dem gleichen

Nenndurchmesser des Flaschenhalses, verschiedene Flaschenformen und -größen können befüllt werden. Stützringdurchmesser: 43 mm. Produktion

Zeiten: für schwach säurehaltige Produkte 24 Stunden zwischen 2 Reinigungszyklen und für stark säurehaltige Produkte 40 Stunden zwischen 2 Reinigungszyklen

Zyklen. Die gefüllten Flaschen werden mit einem aseptischen Kunststoff-Schraubverschluss / Schnappverschluss (mit Single Use Plastic / SUP) verschlossen

(Zusatz) vor dem Ausstoß aus der Maschine. Leistung: 400 V - 3 Ph - 50 Hz - ± 125 kW. Druckluft: 20-40 m3/h @

8 bar. Peroxid (H2O2): <5 Liter/h mit 1.000 ml Flaschen. Dampf: 150 kg/h bei 6 bar / 150 °C. Wasser: 12 m3/h. Edelstahl

Stahl-Bedienpult mit Siemens S7 SPS und Touchscreen-Bedienpanels. Produktionsstunden: 62.371 Stunden. Gesamt

Abmessungen Füller: ± 900 x 240 x 600 cm. Gewicht: ± 9,500 kg.

Der aseptische Flaschenfüller ist eine vollständig geschlossene, lineare Maschine mit einer extrem kleinen aseptischen Zone. Effektive Flaschenabfüllung

und Verschlusssterilisation mit Peroxid-Technologie (H2O2). Berührungsloses Füllsystem mit Füllventilen mit

elektromagnetisch-induktive Durchflussmesser. Verdrängungsströmung zur Zuverlässigkeit halten aseptische Bedingungen in der

aseptischen Zone. Integriertes Ventilblockmodul inklusive Sterilluftaufbereitung auf der Oberseite der Maschine. Schaumreinigung

Station zur automatischen Maschinenreinigung. Niederdruck-Luftversorgungseinheit. Verschließeinheit in der aseptischen Zone. Einfach

Handhabung unterschiedlicher Flaschenformen und -materialien bei gleichem Halsdurchmesser / schnelles Umrüsten. Niedriger Restsauerstoff

Füllstände dank Stickstofftechnologie, Kopfraumspülung mit Stickstoff. Hohe Flexibilität für kleine Chargen.

Funktionsprinzip: Paletten mit vorgeformten Flaschen werden manuell in den Abwurfbehälter eingebracht. Der Behälter führt die

Flaschen bis zum Entschlüsseler (Lanfranchi 2L-SR-16, Baujahr 2017, Siemens S7-300 SPS) und der Entschlüsseler fügt die Flaschen 1 hinzu

um 1 auf dem Leerflaschenförderer. Der Flaschenförderer transportiert die leere Flasche zur Abfüllmaschine. Die

Das Transportsystem besteht aus dem Antrieb mit den angetriebenen Transportketten und den daran befestigten Zellstäben.

Die Zellenbalken nehmen die Flaschen (jeweils 10 Flaschen pro Zellenbalken) am Stützring auf und transportieren sie zum

Stationen. Der Transport erfolgt schrittweise in einzelnen Zyklen. Die Transportketten befinden sich außerhalb der

aseptischen Zone. Die Flaschen werden zur Flaschensterilisationsstation transportiert. Das Innere der Flasche und die äußere

Hals (bis zum Stützring) werden mit einem Wasserstoffperoxid-Aerosol und anschließendem Einblasen von Heißluft sterilisiert. 2 Schritte für

Sprühen des Wasserstoffperoxid-Aerosols, 2 Schritte Verweilzeit, 3 Schritte zum Trocknen mit heißer Luft und 1 Schritt zum Trocknen und

Spülen mit Stickstoff. In der Füllstation füllen magnetisch-induktive Durchflussmesser das Produkt ab. Spezielle Füllventile

und Füllstutzen reduzieren die Schaumbildung. In der Verschließstation werden die Flaschen mit Schraubverschlüssen (mit Single Use

Kunststoff / SUP-Zugabe). Die Verschlüsse werden einzeln aus einem Magazin entnommen und der Verschließstation zugeführt. Gesteuert durch

Die Maschine läuft, die Verschlüsse werden sterilisiert, positioniert und die Flasche verschlossen. Die Flaschenverschlüsse werden sterilisiert

mit einem Wasserstoffperoxid-Aerosol und anschließender Heißluft. Die Greifer zur Flaschenentnahme entnehmen die Flaschen gleichzeitig

aus zwei Zellriegeln (2x 10 pro Entnahme) und legen Sie diese auf das Entnahmeband.

Inklusive Zu- und Ablufteinheit (Luftkanal), Wasserstoffperoxid-Spender und Handbüchern in deutscher Sprache.